SIS

Selective Inhibition Sintering

SIS is an additive manufacturing (AM) technology in which parts are built layer-by-layer from a powder base material. The core idea of the SIS process is the prevention of selected areas of powder layers from sintering. SIS may be considered a contrary approach to the Selective Laser Sintering (SLS) process in which selected areas of powder are sintered by a fine laser beam. SIS takes advantage of bulk sintering in the body of the part, while inhibiting sintering at the part boundaries.

The advantages of the SIS process are:

-

Low Cost: The machine will be far less expensive than the equivalent SLS machine because the high power laser generator of SLS is replaced with an inexpensive heat element

-

Speed: The process is fast because the entire layer undergoes bulk sintering

-

Accuracy: The dimensional accuracy and surface quality is high due to the high resolution inkjet printer used in combination with fine powder particles

-

Multi-color parts may be fabricated if various colors of the inhibitor are deposited (as in color inkjet printers)

-

No contamination of parts, material, or furnaces

-

Great potential of printing large parts

-

Platform technology for metals, plastics and ceramics.

-

Currently the only technology that has the capability of printing ceramic parts

SIS- Ceramics

SIS-Ceramics is a layer based SFF approach used for 3D printing ceramics. During the printing process of SIS-Ceramics, a solid powder S is used to define the boundaries of the part by being deposited into the paved building material. The complete printing of powder S is de facto a coating of the part which is also loose powder before sintering. During the sintering process, the powder S keeps loose due to its higher sintering temperature while the building material turns into a solid piece. The solid powder S serves as the sacrificial mold to separate the part from the surrounding when sintering is complete. The coating is broken by simply brushing away the powder S and the final part is obtained.

USC

SIS- Metal

Since the mid-1980s, Selective Laser Sintering has been utilized as a prominent additive manufacturing technology to meet the needs associated with obtaining 3D parts. However, as the search for faster printed parts with higher resolution increased, an alternative cost-efficient process was desired to meet such demands. With all in mind, Behrokh Khoshnevis invented the Selective Inhibition Sintering process for metals.

An SIS-Metal process has been developed based on microscopic mechanical inhibition. In this process, the inhibitor (typically a ceramic salt or carbohydrate solution) is printed in selected areas of each metal powder layer. The active ingredient (salt or carbohydrate) re-crystallizes when water evaporates under moderate heat. Later, during bulk sintering, it decomposes to second phase metal oxide or carbon. The decomposed solid particles cover the surface of affected metal powder particles and exert a retarding force which inhibits sintering. The SIS-Metal process has numerous advantages including: reduced costs in equipment when compared to similarly capable technologies such as Selective Laser Sintering (SLS), increased speed/efficiency as the entire layer is sintered at once and inhibitor need only to be deposited at the periphery of the part, high dimensional accuracy and surface quality, multi-color part fabrication with the use of a commercial inkjet print head, no contamination of parts, materials or furnaces and a great potential of building large parts.

> Step 1: A thin layer of metal powder is spread over the build tank.

> Step 2: Inhibitor is deposited along the layer profile with a small- orifice nozzle or inkjet print head. Repeat Steps 1,2 until the entire part has been completed.

> Step 3: The part is bulk sintered in a conventional sintering oven under appropriate atmosphere.

> Step 4: The inhibited regions are removed, revealing the desired part and its negative.

* This Project has been supported by the National Science Foundation Grant Number 1343480.

SIS- Plastic

Since the mid-1980s, Selective Laser Sintering has been utilized as a prominent additive manufacturing technology to meet the needs associated with obtaining 3D parts. However, as the search for faster printed parts with higher resolution increased, an alternative cost-efficient process was desired to meet such demands. With all in mind, Behrokh Khoshnevis invented the Selective Inhibition Sintering process for plastics.

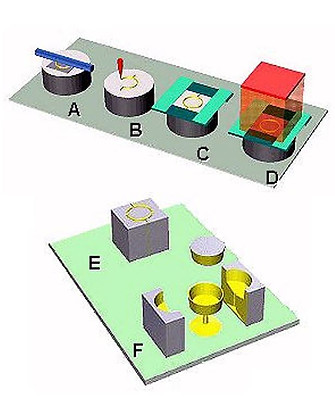

A. It starts by laying a thin layer of powder slightly above the previous layer, by sweeping a roller over both a powder supply tank and the build tank.

B. Then, the areas of the powder bed selected for sintering inhibition are wetted by a printer.

C. A radiation-minimizing frame is positioned to prevent areas of the powder layer which lie outside the part envelope from sintering.

D. The entire layer is then sintered with a blast of thermal radiation from an infrared heater. In the end, a solid polymeric block remains that is totally sintered except for those areas wetted by the inhibitor liquid.

As implemented on the alpha machine, the heater is a coiled nichrome wire that is mounted on a carriage. This allows the heating element to be passed over the surface of the powder bed. Steps A-D are repeated until the part is completed.

E. The final part can be easily extracted from the surrounding material.

SIS- Publications and Awards

Asiabanpour, B., Khoshnevis, B., Palmer, K., & Mojdeh, M. (2003, August). Advancements in the SIS process. In Proceedings from the 14th SFF Symposium, Austin, TX, USA (pp. 25-38).

Asiabanpour, B. (2003). An experimental study of factors affecting the Selective Inhibition of Sintering process.

Asiabanpour, B., Palmer, K., & Khoshnevis, B. (2004). An experimental study of surface quality and dimensional accuracy for selective inhibition of sintering. Rapid Prototyping Journal, 10(3), 181-192.

Asiabanpour, B., Palmer, K., & Khoshnevis, B. (2003). Performance factors in the selective inhibition of sintering process. In Industrial Engineering Research Conference, Portland, OR.

Khoshnevis, B., Asiabanpour, B., Mojdeh, M., & Palmer, K. (2003). SIS–a new SFF method based on powder sintering. Rapid Prototyping Journal, 9(1), 30-36.

Asiabanpour, B., & Khoshnevis, B. (2004). Machine path generation for the SIS process. Robotics and Computer-Integrated Manufacturing, 20(3), 167-175.

Khoshnevis, B., Mojdeh, M., & Palmer, K. (2004). Selective Inhibition Sintering for Fabrication of Metallic Parts.

Asiabanpour, B., & Palmer, K. Systematic approach for Rapid Prototyping processes development.

Asiabanpour, B., Wasik, F., Cano, R., Jayapal, V., VanWagner, L., & McCormick, T. (2005). New waste-saving heater design for the SIS Rapid Prototyping Process. In Industrial Engineering Research Conference (IERC), Atlanta, GA.

Asiabanpour, B., Cano, R., Subbareddy, C., Wasik, F., VanWagner, L., & McCormick, T. (2007). A new heater design by radiation modeling and a new polymer waste-saving mechanism design for the SIS process. Rapid Prototyping Journal, 13(3), 136-147.

Asiabanpour, B., Subbareddy, C., Kolichala, S., & VanWagner, L. (2008). The heat element status assignment algorithms for the selective inhibition of sintering process array-based heating system. International Journal of Computer Applications in Technology, 32(2), 104-109.

Yoozbashizadeh. M. (2012). Metallic Part Fabrication with Selective Inhibition Sintering (SIS) Based on Microscopic Mechanical Inhibition. (Doctoral Dissertation). University of Southern California, Los Angeles, CA.

Khoshnevis, B., Yoozbashizadeh, M., & Chen, Y. (2012). Metallic part fabrication using selective inhibition sintering (SIS). Rapid Prototyping Journal,18(2), 144-153.